An Inventor's Quest for the NHL Pt. 32

Still Breaking, Still Building

This series follows my attempt to develop a product that I dream of getting into the elite levels of hockey. Previously on the Quest: Part 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, Concept Launch, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31

[The experimental approach] is, roughly speaking, the Darwinian method, which Nature seems to rely on to develop her own structures - though she seems to be in less of a hurry and less mindful of the value of life than are most civilized human engineers.

J.E. Gordon, Structures p. 330

Evolution continues on the Uncage; which is a fancy way of saying that I continue to find new ways to break the Uncage and new ways to fix it. (What a surprise!)

First, the zip ties holding the Uncage onto the helmet snapped. So I got ultra beefy ones, which also snapped. So I got metal cable ties, which are still intact.

Then one of the ropes slipped off its retaining post, so I added some whipping. And one of the ropes frayed at the retaining posts, so I added chafe sleeves.

This new and improved Uncage lasted maybe five shots at 60+ mph before it failed too. This time, one of the ropes snapped just outside of the chafe sleeve. Interesting!

Even though I watched the slo-mo video of the failed test and looked intensely at the broken rope for many minutes, I couldn’t figure out what caused the failure. My best guess was some sneaky chafing, because the failure happened right where the sleeve ended. Maybe the sleeve itself caused the chafing.

My solution?

Try to take chafing completely out of the equation as best as I could. I sketched a few ideas.

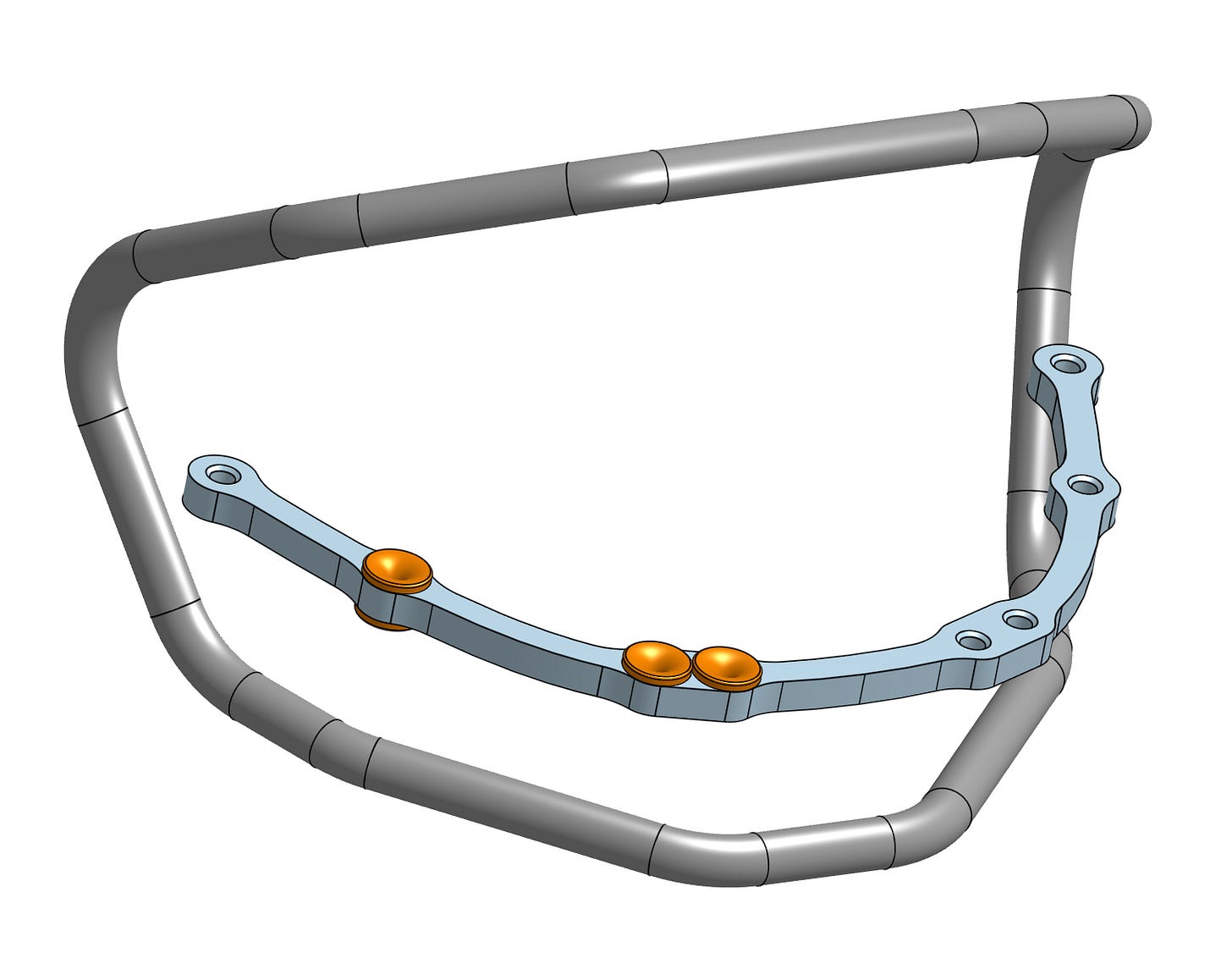

Then took to CAD, where realistic dimensions turned my beautiful thoughts into abominations. But eventually, after enough fiddling, I came up with an idea that seemed reasonable.

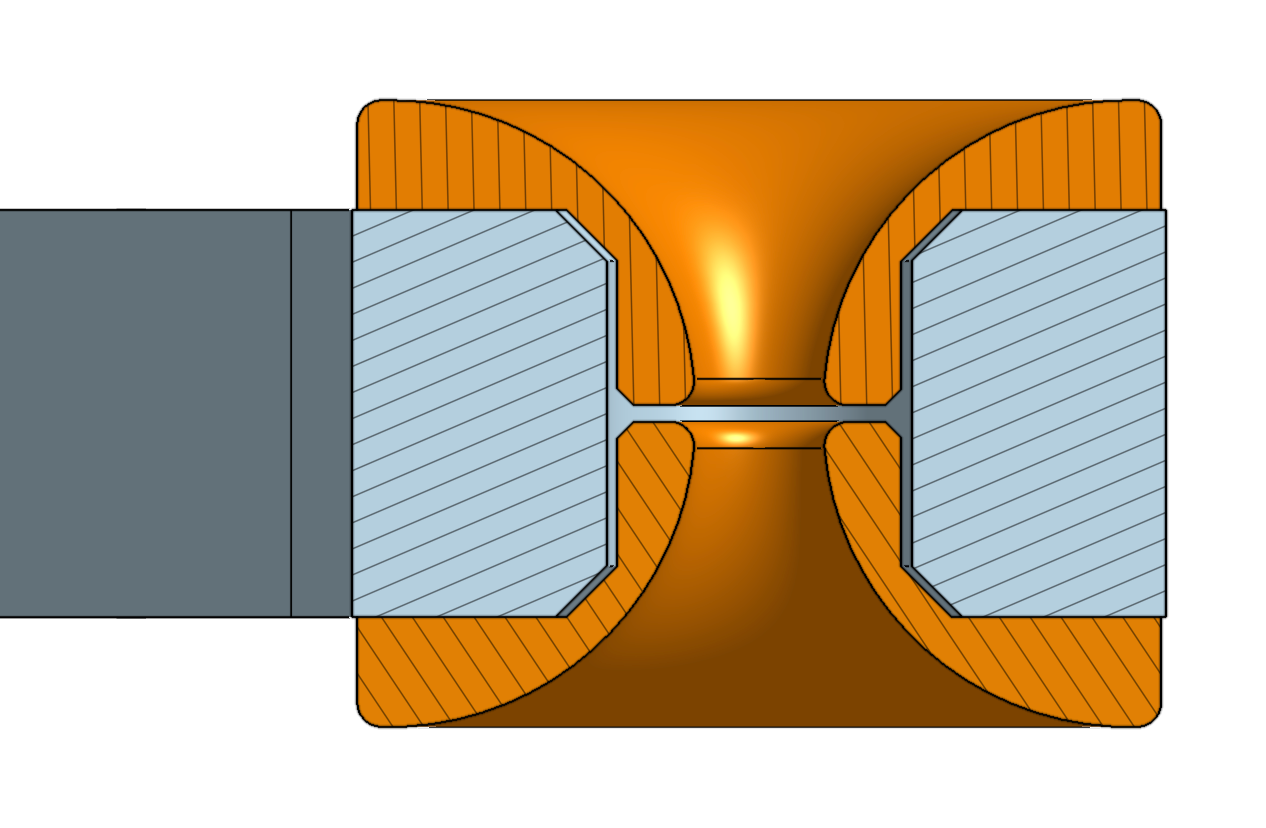

The crossbar would be laser cut steel (for this prototype anyways – I’ll round the corners if this design proves itself). The orange pieces would be 3d printed inserts that I’d glue into all the holes to give a ridiculously smooth transition for the ropes.

I think that’s about as well as I can do to prevent chafing but I wanted a belt and suspenders approach, so I started brainstorming how I could add a better chafe guard to the rope itself.

I looked for other possibilities, but really, the chafe sleeve seemed to be the best bet. If only it was longer. Like maybe it could go the whole length of the rope. Like a … double braided rope.

Don’t you love re-inventing things that already exist? Though in this case, nobody makes double braid rope in the diameter and the material that I want, so I’ll have to make my own.

Slipping one rope inside another is easy enough.

But turning that into a loop within a loop? Slightly trickier. There is an established method, but it looks far too complex for my purposes.

At the moment, I’m leaning towards sticking with the locked Brummel splice that I’ve been using and just doubling it up, like so:

Even though the original intention was chafe-prevention, I’m excited about this design evolution from a safety point of view too. Before, my plan was to have enough of a safety factor on the ropes that the metal crossbar would yield before a rope ever failed. That never felt all that comfortable. Now, if something cuts through the outer rope, there is a fail safe waiting inside.

Let’s see if these changes give my metaphorical fish some legs.

Thanks as always for reading,

Surjan

https://xkcd.com/2738/

Some of my first experiences with high strength lines was with a 45lb test braided spectra line when fishing more than 20 years ago. At that time after fishing for 3 days there was a break on one of the strands every 4 feet or so, but the line held. It also is good with being twisted, and doesn't bunch like monofilament did.

I have some 800lb spectra kite lines. My two string kit has lifted me into the air several times, and those lines are less than 1/8 inch.