An Inventor's Quest for the NHL Pt. 23

Questioning the Next Steps

This series follows my attempt to develop a product that I dream of getting into the elite levels of hockey. Previously on the Quest: Part 1, Part 2, Part 3, Part 4, Part 5, Part 6, Part 7, Part 8, Part 9, Part 10, Part 11, Part 12, Part 13, Part 14, Part 15, Part 16, Part 17, Part 18, Part 19, Part 20, Part 21, Concept Launch, Part 22

The entirety of what I have left to do boils down to a single question: “How do I make sure that the Uncage is ready to protect real, human faces?”

The answer to that question is more questions: What should my testing look like? What would I consider a successful test?

And those questions branch out into more questions and those into more questions, until finally, I get to questions that I actually know how to answer. But answering them is not so easy. In such large numbers, it feels like the questions form into a bait ball as a defense mechanism. They swirl around in mesmerizing patterns, making it impossible for me to focus on a single one.

For a while, I was overwhelmed by how much I had left to figure out. But I knew that the less stuff I held in my head at the same time, the better. So each time a new question popped into my head, I caught it, and wrote it down until the ocean of my mind was a barren wasteland – just how I like it.

Here’s (a more organized version of) the questions I caught and wrote down as well as my attempts to answer them.

What should my testing look like? Would I feel comfortable just using existing Hockey Equipment Certification Council (HECC) testing, since they’re the standard for current masks and cages? No, not really. Their testing speeds only reach 81 mph. Shots in the NHL are regularly higher than that. The HECC testing makes sense for metal cages with decades of empirical evidence behind them. For something as new as my design, I need to prove a lot more.

So if not 81 mph, what speed should I test at? The hardest shot recorded in an NHL event is Zdeno Chara’s ridiculous 108.8 mph shot at the 2012 NHL All Star game. The hardest shot recorded this past season during a game was 101.5 mph (thanks to Mike from SportLogiq for that stat). Currently I’m thinking I’ll shoot for 110 mph, which should give me a reasonable buffer from likely in-game shot speeds.

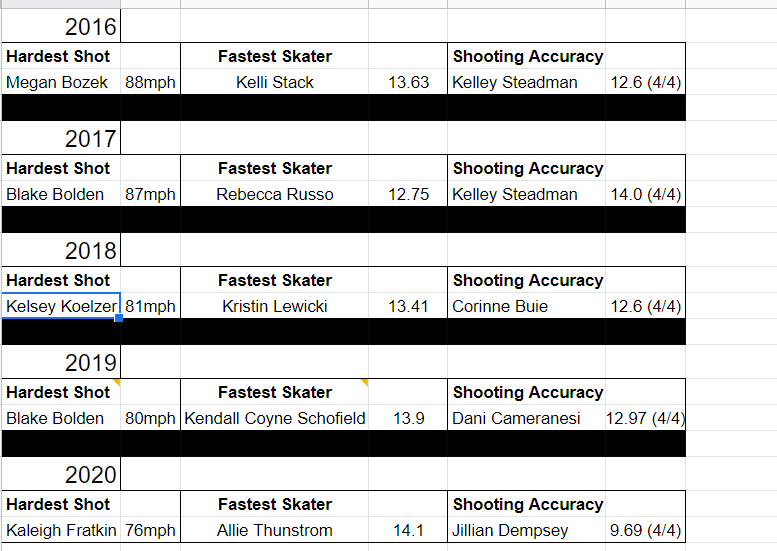

Initially I was thinking that would be the standard for everything, but it might make sense to have separate standards for women’s hockey. Why should they have to wait for extra testing because the NHL has some 6’9” giants? You can see the PHF hardest shot speeds below, courtesy of Mike and Carlie. Unfortunately, I haven’t been able to get my hands on any in-game shot speeds just yet, but it seems reasonable that they’d be similarly slower than an All Star game. So for the PHF/PWHPA Uncage, I’m thinking a 90 mph top speed for testing.

What about durability testing? I plan to use slower speed shots (near the average shot speed in each league) to better understand the durability and lifespan of the Uncage. What’s a reasonable lifespan? To start, I’ll keep the lifespan of the cage artificially short until I’m able to build up a bigger body of testing. Perhaps even as short as a week. Goalies take ~5 to the cage per practice, so a total of ~30 shots a week.

From what angles can I expect puck impact? In talking to goalies, all of them! This is one of the other areas I’ll deviate from the HECC, which only tests a few angles.

Is it reasonable to assume that the hardest shots would only come from straight on? Yes, but it’s not 100% guaranteed, so still worth testing off-angle shots at those higher speeds.

Do I need to prevent sticks from going through the cage? That’s a tricky one. Current cat eye cages allow sticks to get through and cause injuries, but goalies are willing to take that risk. Can I make a fully protective cage that’s good enough to satisfy those goalies who value visibility above all else? Or would I need to make something that has some small but non-zero risk of a stick in the face? Should I even give goalies that option? That’s all still to be determined. I’m going to try to make the fully protective version first and check the feedback.

What ambient conditions should I test for? At the highest levels, pucks are frozen before play to reduce bounciness. So I should test room temp and frozen pucks. What about the cage itself? The HECC test spec has some guidelines for simulating a cold environment for the cage, so I’ll use that. What about sweat and water? Goalies are always squirting their faces with water, so a shot to a wet cage is a reasonable scenario. During my testing, I can soak my cage with salt water to knock out the sweat question as well – though I hope no one sweats that much in real life. How about sports drinks? Yes, goalies drink sports drinks through their cages. Pretty sure nobody’s checked how Gatorade affects the strength of Dyneema, so that goes on my list too.

Should I account for manufacturing variables? Yes. If I’m making a very small quantity to begin with, I can have an extremely high standard. But nothing can be manufactured in the exact same way every time. So I’ll need come up with an acceptable range for things like rope tension and placement of the metallic bar. How do I measure rope tension? I found these tension meters. But there’s a bunch of different ranges, so which one to buy? I’ll use this technique of pulling on the string and measuring deflection to find a ballpark tension.

What should my test setup look like? How should the helmet be secured? For this, I think it’s best to turn to established testing standards. I was tipped off by Justin of Fusion Goalie Masks that some NHL mask testing had been leaked online.

If you read the fine print at the bottom you can see the testing was done with a Hybrid III head form. The Hybrid III is a crash test dummy that costs $250,000 – slightly out of my budget. The neck also allows for movement, which means that more of the puck’s energy is going towards moving the head and less towards trying to break my cage. I want to err on the worse case side in my testing.

The HECC standard, on the other hand, calls for use of this slightly sad-looking head, made from urethane (which seems energy absorbing) but with no movable neck. I’ve reached out for a quote but I’m guessing it’s going to be absurdly expensive. If it is, my plan is to cast a head of my own – but probably not my own head – with urethane casting resin.

Is a goalie’s head always free to move back like it is in those test setups? Could there ever be a scenario where the goalie’s head is braced against the goalpost, forcing all of the puck’s energy into the cage? For this question, Phil, a fellow mechanical engineer and former pro goalie, had some great insight. The only situation he thought that could possibly happen is when a goalie goes into reverse-VH to seal off his/her post. It is possible, though unlikely, that a goalie would lean their head against the post to plug every little hole. But even if they were to get hit in the face in that position, it would be the side of their head against the post, so the head would be free to move backwards. I want to be conservative in my testing but I also don’t want to test things that will never happen.

How will I make sure the cage didn’t break after a test? I’ll look at it. How will I make sure the cage didn’t flex backwards and hit my fake goalie’s face? I can cover the dummy’s head with a thin layer of play-doh, which will clearly show indentations if any part of the Uncage gets pushed back.

How will I shoot the puck during testing? With the help of a bunch of very creative people on The Prepared Slack, I considered everything from an electromagnetic rail launcher to a clay pigeon thrower, but I may have found the simplest possible solution: a local business that has a puck shooting machine for off-ice training. For quick iterations, I can continue to use my giant slingshot.

As you can tell, there’s a lot of development and testing left to do. Just like the questions, I’m going to break it down and take it one step at a time.

Thanks as always for reading,

Surjan