This series follows my attempt to develop a product that I dream of getting into the NHL. Previously on the Quest: Part 1, Part 2, Part 3, Part 4, Part 5, Part 6, Part 7, Part 8, Part 9, Part 10, Part 11, Part 12, Part 13

Hello friends,

Lots to catch you up on. I’ve made some progress on the problem that’s been plaguing me since the beginning of this project – the strings in my cage going slack after taking a few impacts. My cage is a tensegrity structure which relies on the tension in the strings to maintain its shape, so that slack is kind of a big deal. I’ve tried different knots and stringing patterns, but nothing worked.

So I took a different approach.

Previously, I had been looking at the cage as one big convex net that I had to adjust all at once, as a single entity. This time, I focused only on the crossbar, the one rigid element in the net. In previous iterations, the strings going slack always happened at the same time as the crossbar shifting around. My thought was that, if I could eliminate one problem, maybe the other problem would be eliminated as well. So I concentrated on answering one question: how can I fully constrain the crossbar’s position with the least amount of connections?

In my mind’s eye, I pictured the crossbar floating in position without physical connections. When I mentally pushed and prodded the floating crossbar, there was nothing to stop it from translating or rotating. In other words, it was fully unconstrained. One by one, I started adding connections.

Here’s an example of what I was picturing. I imagined two strings connecting the crossbar to the frame with a total of six knots.

With those constraints, I could still rotate the crossbar and translate it up.

That’s what I was seeing in my head, usually when I was in bed trying to fall asleep.

I don’t know if other people do it too, but I’ve enjoyed thinking in 3D ever since high school, when I played around with 3D animation on a program called Blender. If I remember right, I made some brilliant animations of a snowman that slowly falls apart as it tries to wave and, for some unknown reason, a VeggieTales-esque take on Moses parting the Red Sea set to the Bee Gees’ “Stayin’ Alive”. You can practically connect the dots from those animations to what you’re seeing from me now.

Back to my mental imagery. I thought if I added one more string, with three more knots, the crossbar would be fully constrained.

I had my starting point. Now, I could think about how to make improvements. I chose to try to minimize the number of knots. Knots can reduce the strength of a line by 30-40%, so naturally I wanted to have fewer weak points.

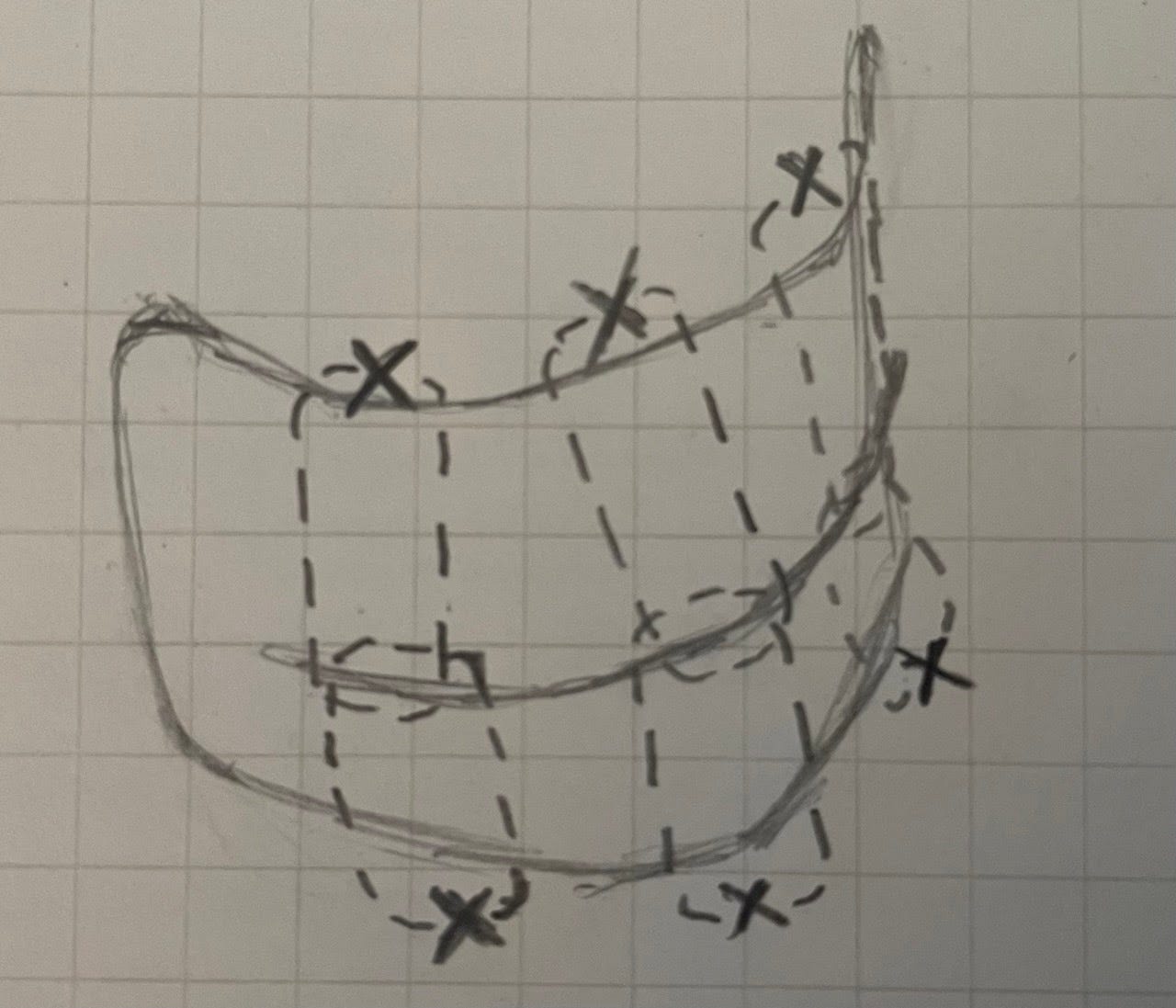

After mentally moving ropes around for a while, I came up with this configuration.

Six loops with six total knots instead of my original three strings with nine total knots. Not only do I get fewer knots, but I also get more coverage across the face, for free.

In my head, the crossbar was fully constrained in this configuration. But it was just a mental model and I needed a mockup to make sure I was right.

Turns out I wasn’t completely right. The crossbar could still swivel. I definitely could have reoriented the lines to limit that movement, but I liked the orientation for strength considerations, i.e. aligning the strings to most directly oppose the force of a puck. So I simply added one more string on each side.

I had a configuration I liked, so it was time to make a real version and put it to the test. My biggest concern was the knots. I had reduced the number of knots, but I was still worried about the strength and stability of the ones I did have. And here’s where I got some luck.

As I mentioned in my last update, I was flirting with the idea of finding a different material for my strings in the hopes that it would absorb more energy than Kevlar and reduce head acceleration. I eventually abandoned the idea because it would add too much scope. But while I was doing some idle, initial searching, I found this pretty incredible rope made from Dyneema – a fiber that’s similar to Kevlar.

It wouldn’t reduce head acceleration, but it had a few other advantages: Dyneema has better UV resistance than Kevlar and the braided line has better abrasion resistance than the twisted yarn I was using. It’s also absurdly strong. At only .059” / 1.5 mm in diameter, it can hold 714 lbs / 324 kg.

The best part though – and here’s where the luck came in – was this infographic I came across on the manufacturer’s website.

I had only really considered knots for my design, but after seeing this, I was pretty intrigued by splices. My impression of splices was that they were incredibly difficult to do. I pictured that you had to completely unravel the braiding of two segments of rope and manually re-braid them together. That may have been true back in the day, but nowadays, it’s much easier. The rope I’m using is hollow in the middle, so you use a needle to pull the rope inside of itself. Sort of like a snake eating its own tail.

After some searching and experimenting, I found this locking looped splice, which seemed like it would be perfect.

I made a prototype with the new rope, stringing pattern, and locking splices.

As you might have noticed, I couldn’t splice all of the connections. Splicing requires slack and the last few ropes have to be tied under tension, so I was forced to use a few knots.

No matter, I was still feeling really optimistic. Visually, it was the closest the cage has ever looked to a real product.

I strapped it onto a helmet and used my puck pendulum to whack the cage with a puck going about 15 mph. After about the 20th impact, one of the lines went slack.

Annoyed and hugely disappointed, I tried to figure out the issue. I didn’t think there was any slippage in the splices, but I couldn’t be sure. I carefully measured the length of each segment of rope, retied the knots, and retested.

The line went slack again, but I could not find the culprit.

For a whole evening, I retied and retested over and over again. I measured every possible thing I could try to measure, but I came no closer to finding an answer.

I was absolutely crushed. It felt like the end of the project, again. Maybe it could be a good design in theory, but what if in reality, I just couldn’t get rid of the slack? Maybe I was the problem. What if I just wasn’t the creative inventor that I wanted to be? Should I just go back to a regular desk job?

That night, I watched the Olympics, where Mikaela Shiffrin gave an emotional interview after failing to finish the slalom, an event she was favored to win. I felt this part deep in my soul: “Makes me second guess the last fifteen years — everything I thought I knew about my own skiing” In those fifteen years, she’s won three Olympic medals, seventy-three World Cup races, and three overall World Cup titles.

I wasn’t the only one to take a momentary failure as evidence that nothing I have ever done or ever will do will be any good, even though that’s objectively not true.

Not even Leonardo da Vinci was immune.

After seeing those examples, I knew this feeling wasn’t a particular shortcoming of mine, just a part of the normal ups and downs of trying and failing. That was comforting.

The next morning, I had an idea on how to isolate the problem.

I used a zip tie where I had been using a knotted string. And, lo and behold, the slack didn’t come back. I had narrowed down the problem. The locked splices were working better than anything I’d done before, but those few knots that I’d been forced to use were subtly shifting or slipping just enough to cause issues.

I haven’t tested solutions just yet, but I’m feeling hopeful about my chances of making a loop with a soft shackle, which would cut the total number of knots in my cage down from six to just three. And those knots would be stopper knots, which I think would be less prone to slippage.

As always, I won’t know till I try.

Thanks for reading,

Surjan