#42 - From Failure to Failure

Leaf-Inspired Trunk Pt. 4

Previous Parts in This Series: Part 1: Intro, Part 2: Mold Unknowns, Part 3: Mold Attempt #1

I feel like failure is overly romanticized. There’s a book’s worth of quotes like Churchill’s, “Success consists of going from failure to failure without loss of enthusiasm.” It sounds nice at first, but on second thought, Churchill’s successful person sounds inhuman. Imagine the final buzzer sounding on the Stanley Cup Finals and seeing the losing team milling around and happily chatting to one another, instead of the usual scenes of despair. The magnitude of the occasion would be lost. Winning the Stanley Cup would feel like the time I won my beer league Division 5B championship (humble brag), except with a bigger trophy. The significance of an event is told by the emotions involved. But is it wrong that the measure of success is how unhappy you would be with failure? Maybe Churchill was onto something. Maybe with the right attitude, Sisyphus could’ve been a little more enthusiastic about his boulder.

But I’m not Churchill, so I was annoyed as I worked to figure out what went wrong during last week’s failure. Why was my mold so flexible?

My hope was that the plaster I’d used to build my mold was expired and that non-expired plaster would be stiffer. I hoped that I could just build the same thing with new materials and be done. Thanks to modern convenience, it only took two days for my hopes to be crushed.

So I kept searching for reasons. After wildly flinging accusations here and there (I even looked up the humidity on the day of the failure), I finally laid the blame where it was deserved: on my idea. Turns out that making a mold solely from plaster is a bad idea for something as big as a trunk; it would take a huge amount of plaster for the mold to be stiff enough to hold its shape.

This kind of thing is the hardest part of a self-directed study. I was back to the same spot I started out a week ago, and it was hard to refocus. There were a hundred things I could do that would be more fun than thinking about molds. And I did. The first few days after the mold failure, I didn’t work that hard. I tried to make a little progress every day, but I also indulged in a bit more Dirt Rally 2.0 than normal.

Slowly, the desire to finish the mold came back on its own as a new plan formed. The plan was stitched together from a few observations. The first observation was that no reasonable amount of plaster would make a stiff mold. So clearly, I had to add more of another material. The second observation was that the inside of the failed mold ended up drying out when exposed to air. So I should work in stages and allow each stage to dry separately. The third observation was that I had more fiberglass than natural fiber cloths on hand. So I’d use fiberglass as my reinforcement. My goal was to make a non-toxic mold, not an all natural one.

I did a couple quick tests to hammer out the details and then began.

For the release, I chose mineral oil over painter’s tape. It worked well with plaster in a test, it was easier to apply, and it was less wasteful.

On top of the mineral-oil-smeared trunk, I laid down one layer of plaster. I used smaller strips than before so I’d have time to smooth the plaster out.

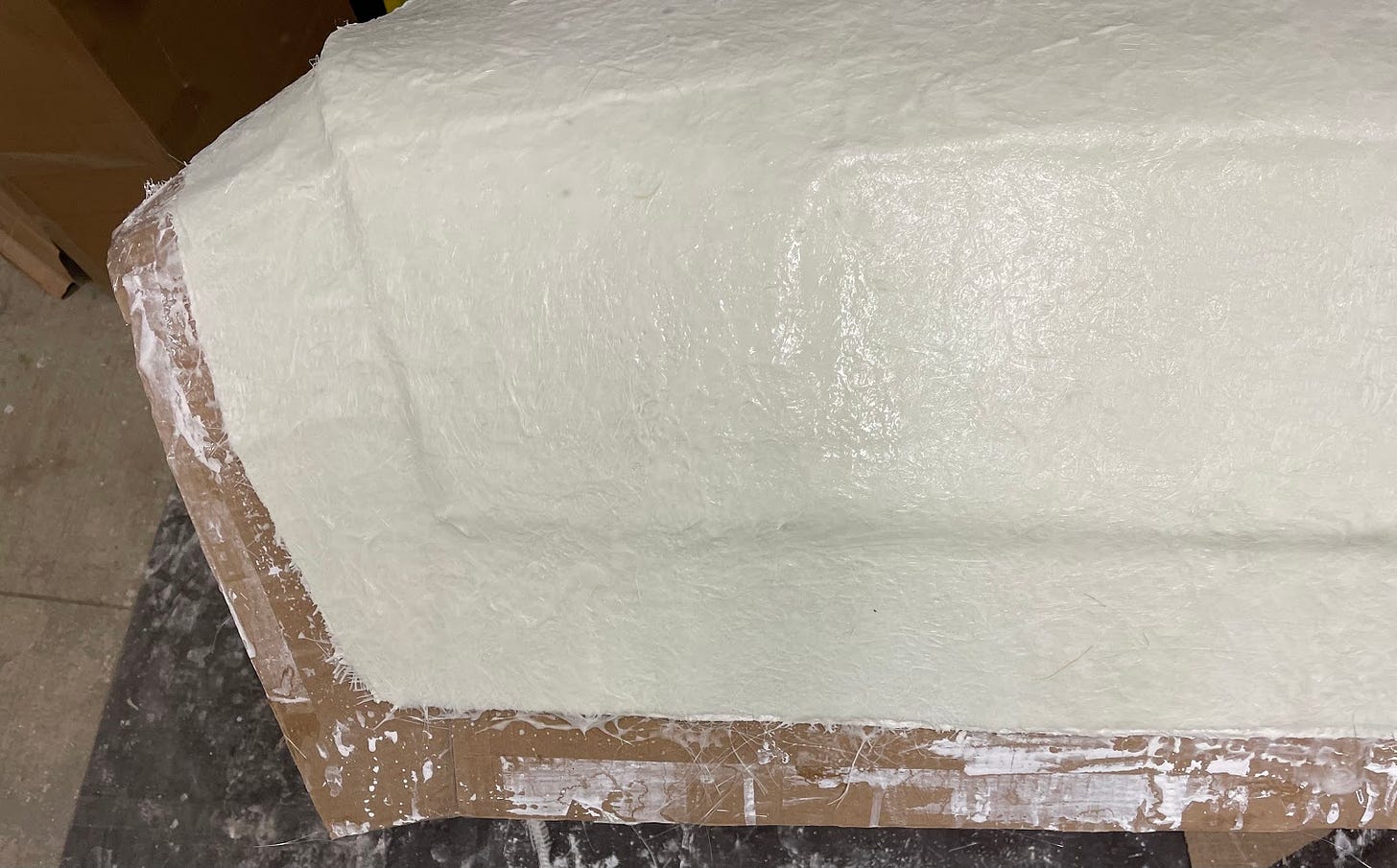

After the plaster dried, I layered on a woven fiberglass cloth with casein glue. This cloth conforms well to curvature, so it would support every square inch of the plaster well.

After the first layer of fiberglass dried, I added another. This time I used a chopped strand mat. This fabric is thicker than the woven cloth, so it builds up stiffness quickly.

After this fabric dried, I decided to pull the mold off. I had a feeling I would need to add another layer, but it would be worth taking the mold off and checking the stiffness before I went further.

So I took the mold off and everything was perfectly fine. Why are there no pictures? Because everything is perfectly fine and there’s nothing to see here.

Okay, maybe there was a slight hangup.

Only a small one.

I guess mineral oil doesn’t work that well as a release. Somehow, I was less downcast about this failure compared to the last one. It’s like it was so bad, the only reasonable reaction was to laugh.

I’ll have to make another mold of course, but I might move on to another part of the project to give myself a little bit of a mental break before I tackle this cursed mold again.

For some reason, I keep remembering a scene from the movie Holes, where a young Shia LeBouf sings,

If only, if only, the woodpecker sighs,

The bark on the tree was as soft as the skies.

I love when readers get in touch. Leave a comment, reply to this email, email me at surjan@fastmail.com, or find me on LinkedIn.

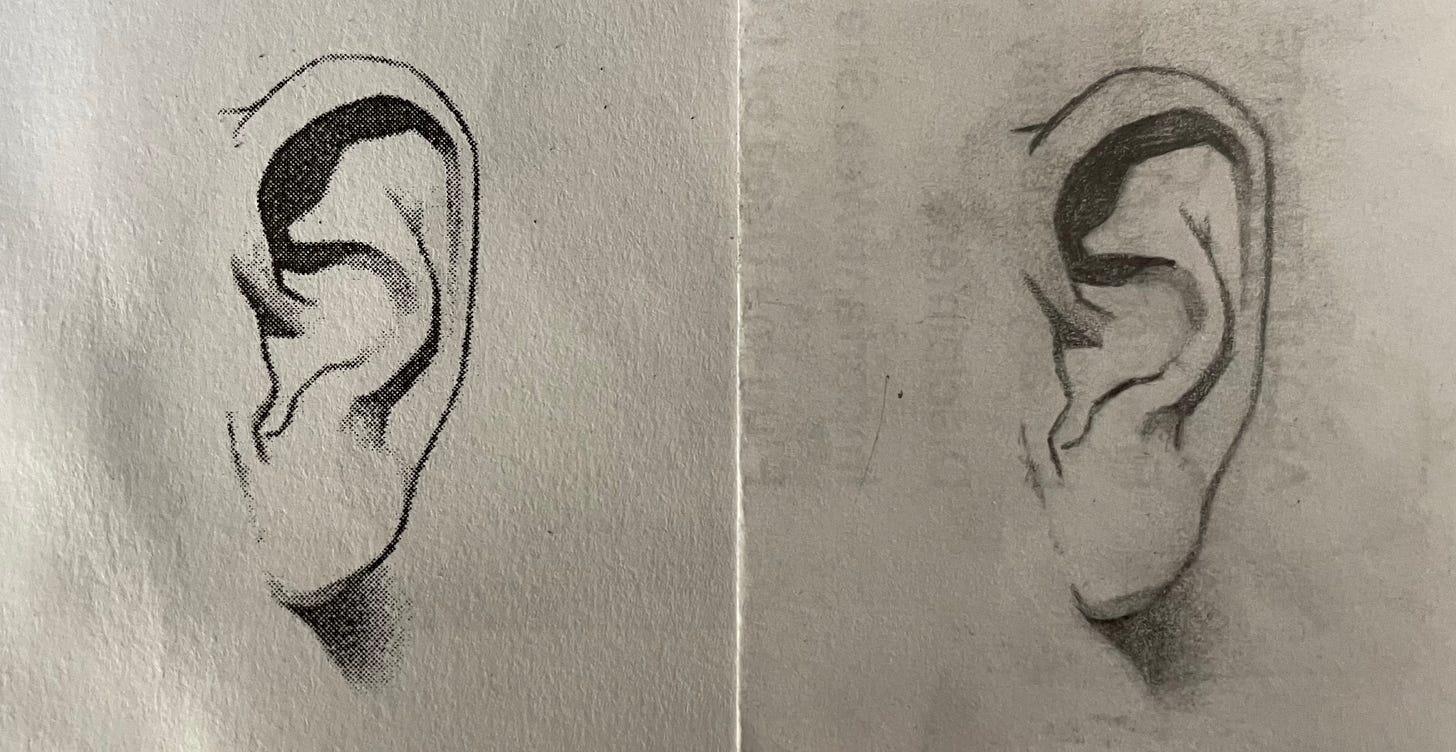

Drawing exercise #31. If you missed it, here’s why I’m learning to draw.

use plaster bandages ( the one used by doctors to make plaster casts ) they work great. When i was an architecture student we used to make light weight sculptures using this technique. They are very easy to use and the fabric inside makes it stiff and break resistant. a bit more expensive though .

Back in the mid 80’s some guys wanted make a replica of the Lamborghini Countach the story I heard goes something along the lines of the guyshired one for a few days and set to making molds of the panels. Needles to say the limited time resulted in not fully cured molds which “sagged” somewhat - but they pressed on many ill fitting fiberglass panels were made. The point is your in good company and as frustrating as failure is if everything worked we would never learn anything.

Good luck