#29 - Another Epoxy Alternative: Milk

Continuing Explorations of Natural Glues in Composites

I made a composite panel using fiberglass, milk, and Borax.

This was my second experiment with a natural glue; the first was a hide glue composite. Even though the hide glue worked surprisingly well, I have wanted to try a milk-based glue since I read about in J.E. Gordon’s The New Science of Strong Materials. It’s called casein glue (casein is a milk protein) and it’s apparently been around since ancient Egypt. You might remember that the same was true of hide glue. At this point, I wouldn't be surprised if Egyptologists uncovered a tube of super glue.

But I was more interested by the use of casein in the wooden airplanes of WWII. The success of a natural glue in a demanding situation so recently was encouraging.

A snippet from an old-school Casco Gluing Guide.

There are tons of recipes for casein glue -- just check out the selection in this book from 1906. The one thing they all have in common is, well, casein. So that’s seemed like a good place to start.

The process is similar to cheese-making; curds are separated from whey. In our case, nonfat milk is preferred -- fat makes a weaker, though probably tastier glue. To separate out the curds, I heated milk until it was warm to the touch, added vinegar (1 part vinegar to 8 parts milk), and gently stirred. Like magic, the curd started to string together and clump into a squidgy ball. Curd is not pure casein -- there’s still some fat and sugar from the milk and vinegar from the curd-making. Purification is possible, but most recipes only suggest rinsing off the vinegar. So that’s all I did. At this point, the glue tastes like a low quality, flavorless mozzarella ball. Of course I tried it. Isn’t that the whole point of edible ingredients?

The next step is dissolving the casein with a base; recipes call for bases ranging from baking soda to Borax to lye. Confession time: I got a C in chemistry, so I have no idea what’s going on in this step or how it works. If you’re a chemist who can explain things simply, please get in touch! What I do know is that a mixture of just water and casein stays clumpy. Adding the base allows the casein to dissolve into a smooth, consistent glue (theoretically).

I say theoretically, because my first two attempts were miserable failures. The first time, I made a stinky, yellowish curd from a stinky, yellowish, and expired milk powder. When I added baking soda and water, the casein stayed chunky. It looked like a scene from my childhood: a bowl of Kix that had been left in the milk too long. I’ll spare you the pictures, but it wasn’t pretty.

The second attempt looked a little better only because I used fresh milk. But it stayed stubbornly chunky as well. The only other change I made was warming the water. That was supposed to help break down the casein, but it didn’t.

For the third attempt, I tried following a video recipe. I figured if the casein knew that I had hard evidence that it could dissolve, it would. And dissolve it did. The trick this time was putting the rinsed curd back in the pot over a low flame. Just adding a touch of baking soda in water helped break down the curd into a smooth glue. Sweet!

I tried another sample with Borax instead of baking soda, which seemed to dry a tiny bit stiffer. Recipe sorted, it was time to try my hand at making a panel. Loyal readers know the routine by now. This was my third part from the same mold and I prepped it the same way with release wax and PVA.

I prepared a big batch of glue, starting with four cups of milk, and started wetting the fiberglass. The casein glue was a lot more calming to work with than epoxy or hide glue. Epoxy has a limited pot life. Hide glue has good pot life, but sets quickly when it cools on the mold. Both required me to work quickly, which I’m not good at. With the casein, I was able to take my time and fiddle to my heart’s content.

It seemed like I got the right consistency by thinning my cold glue with a little bit of the Borax/water mixture. I could see the red of the mold through the fiberglass as the glue penetrated down through the fabric. I did play a little air bubble whack-a-mole since the glue didn’t really get tacky. When I shifted the fabric to get rid of an air bubble, the rest of the fabric would shift and create another somewhere else. A similar thing happens (at my skill level) with epoxy, so I’ll probably get better with practice. Three layers of fiberglass later, I was feeling good about my chances. The fabric had all laid down well.

The next morning, I wasn’t feeling so good about my chances. The part was dry but I could see a color difference along all of the corners. Something was funky.

The part released from the mold without any complaints, but the fabric had bridged across the corner without laying down into it.

I questioned my layup, but pictures seemed to show that the part didn’t have any bridging issues the day before. It must have been the glue shrinking. This happened to me with the hide glue -- though in that case, the edges pulled away from the mold. It seems that glues which harden by the evaporation of water always shrink. My watery glue must have shrunk over night and left me with gaps.

The mold-side of the part was still a bit wet, so I left it to dry another day. I think casein glue dries better with air contact, though I might try an oven at some point. The final part worked, which was cool, but it felt even a little less stiff than the hide glue, which was not so cool.

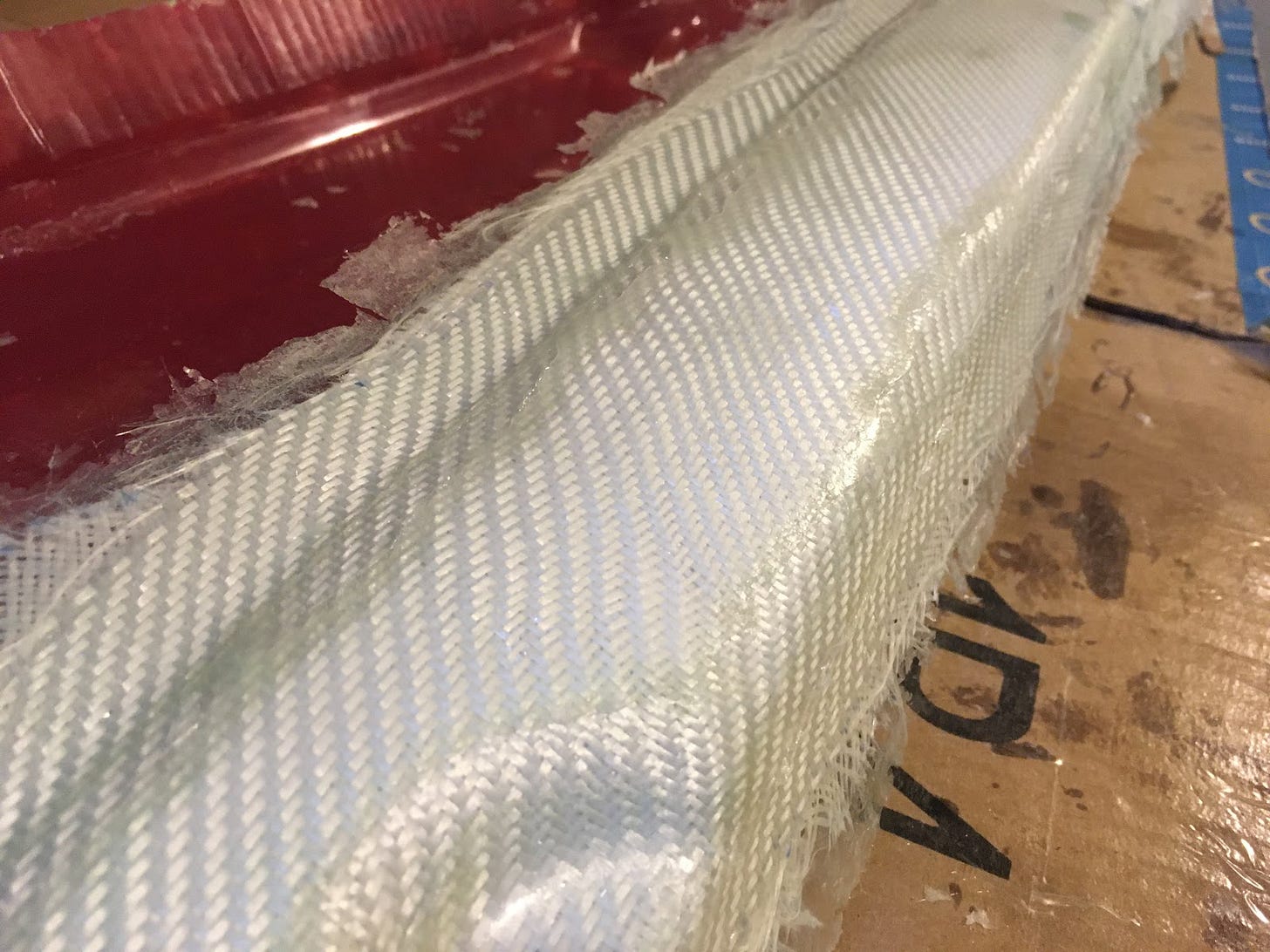

Trimming revealed another issue. When I cut through the part, the edges frayed -- a lot like the hide glue version, but even worse. And again, I’m confused about why it’s happening. Either the way I’m cutting the panel is liquefying the glue or the glue never coated the fibers in the first place. It felt like the glue had penetrated but it’s hard to argue with the evidence.

So now I had three versions of the same fiberglass panel: epoxy, hide glue, and casein. The casein glue was, if I’m honest, the least impressive end result. But I feel the most drawn to trying it again. Luckily for me, I’ve covered my ass in previous posts by saying that engineering is driven more by likes and dislikes than it is by data and “logic”. So I’m going to embrace the irrationality and continue messing around with casein. I like working with it and I like that I have control over the recipe. With epoxy and hide glue, the only choice I have is which one to buy. With casein, there are hundreds of recipes and hundreds of possibilities. Next time, expect an update on the casein experiments as well as a first trial with natural fibers.

Corrections? Questions? Comments? I’d love to have your input. Leave a comment, email me at surjan@substack.com, or find me on LinkedIn.

Drawing exercise #18. If you missed it, here’s why I’m learning to draw.

Did you find a reliable casein glue recipe? I’m keen to hear your results!