The first thing I wanted to do with my Saab 96 was to establish a baseline weight. The cheapest scales used for racing are over $700, so that wasn’t an option. People have used bathroom scales but I’d rather not own sixteen bathroom scales. One idea I thought of was to use the tires themselves. I haven’t searched to see if anyone else has been as genius/dumb enough to think of this. Sometimes it’s more fun to try to answer your own questions.

The Idea

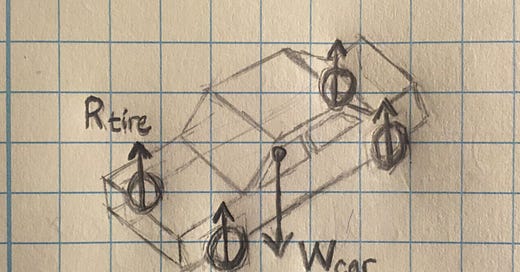

We know that the weight of the car must be reacted by a force from the tires, since the tires are the only thing in contact with the ground (if all is well). Four reaction forces at the tires = the total weight of the car. If the car’s weight was distributed perfectly, each of the reactions at the tire would be the same. But, on my Saab for instance, there’s an engine in the front and relatively little junk in the trunk. So I expect more weight towards the front.

From high school physics, you probably remember the relationship P = F / A, or pressure is force over area. We want to find the force at each tire. So by rearranging, we get F = PA. The pressure is gotten by a tire pressure gauge. The A is the area of the tire in contact with the ground. A quick sanity check is a flat tire. You know, just by looking, when you need to add air to a tire. The rubber sort of sags and pools on the ground. The reaction force stays the same (since the car has not begun levitating or sinking into the ground), but the pressure has gone down. So in response, the area, or footprint of the tire, goes up.

The Weighing

First off, I went around and set all of my tire pressures to the exact same pounds per square inch (psi). I have a decent pressure gauge that I got for $25, so I feel I can be reasonably accurate.

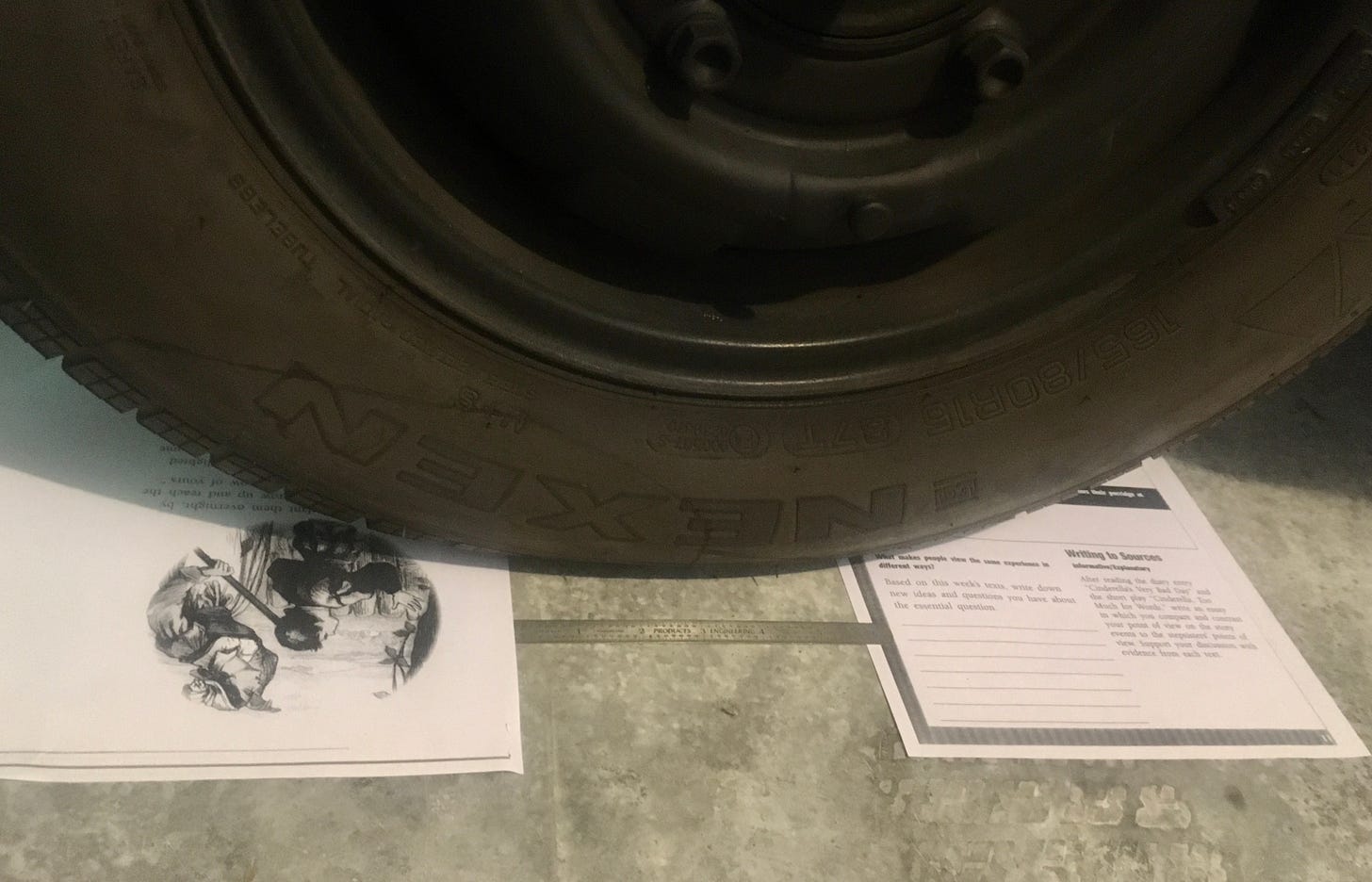

In order to get the footprint, I slid paper in on all sides to find extent of the area of the tire’s contact with the ground. What I measured was a sharp rectangle, whereas in reality, the corners of the footprint are rounded, but I thought that was an acceptable simplification.

What’s difficult is figuring out how to approach the tread. The grooves are obviously not in contact with the ground, but do they still count for the area? I think it depends on the structure of the tire. For an example, let’s think of a book on a table. The feet of the table provide a relatively small area to react the weight of the book. But the high pressures at the feet are not seen by the book. The table’s structure provides a greater surface (the tabletop) for the book’s weight to be reacted.

For my car, the air inside the tire plays the part of the book, the tread blocks as the table legs, and the tire structure between the tread and the air as the table top. So does the tire have enough structure to spread the force over a bigger area like the tabletop? Or do the tread blocks push directly on the air inside the tire (the equivalent of the book sitting on the legs of the table without the tabletop)? I couldn’t reason one way or the other, so I tried both.

The Calculations

To get my forces at the tires, I simply multiplied pressure by the area of the footprint. Pounds / square inch * square inches = pounds. Checks out.

For the version where I discounted the area of the tread grooves, along the width, I subtracted .25 inch/groove * 3 grooves = .75 inches from the measurement. Along the length, there was a 1/8 inch long groove every inch so I multiplied the measurement by 7/8. I ignored the smaller, shallower grooves because I thought they would have the “tabletop” effect I discussed earlier. In other words, there was enough rubber between the groove and the inside of the tire that the force would be distributed enough to negate the groove.

All summed, the version that ignored the tread gave me a total weight of 2,377 lbs. The version that accounted for the grooves gave me a total weight of 1,731 lbs. The larger footprint gave me a higher weight, which makes sense. The weight distribution showed ~55% of the weight on the front tires. That’s in line with what I expected for a front-engined car.

The Result

I decided to drive over to the nearest public scales and get a real weight. For a princely $12, I got the answer: 2040 lbs. I will admit, I did have a bit of a brain fart and filled up on gas before getting weighted. Accounting for the gas that I added, the actual apples-to-apples weight is closer to 2010 lbs. So what does this mean? My immediate thought was that the approach to the tread on my tires should’ve been somewhere in the middle. I went back out to my car and took a closer look. The grooves going around the circumference of the tire were deeper than the ones going across the tire. I redid the calculations only accounting for those grooves and got 1,978 lbs. Only about 30 lbs, or ~2%, off of the actual weight.

Conclusion

So is this a good method? I can’t say for sure, since it’s only one data point. It’s always difficult to tell when you tweak your approach after you have a real result to compare to. In this case, the tweak was something I was already thinking about and was rooted in reality, so it felt reasonably valid.

I’d love to hear other results if anyone tries it. I think it could work well with slicks (which avoid the tread issue entirely). For non-slicks, accounting for tread is probably very dependent on the construction of the tire. Guess and check is likely the only way to go. After the first time, once an approach is established, it might be more useful. The weight distribution seemed very believable and is not really sensitive to the tread / overall weight.

All in all, a cool, free way to weigh a car and a fun experience satisfying my own curiosity.

Addendum: It’s been pointed out to me that I completely ignored the tire’s sidewall stiffness. So the method is probably not accurate for total weight - still could be useful for weight distribution though. This is why I’m sharing my learning! I get to learn from readers as well.

Drawing exercise #6. If you missed it, here’s why I’m learning to draw.

An enjoyable read!

It made me wonder... how about if you were to ink your tire treads, roll the car onto plain paper, draw a couple of marks at the leading/trailing edge of each tire (so you know what to ignore when rolling the car back off the paper), flat bed scan the results, and work out the contact area based on the number of dark pixels in the image (you could get the image scale from the scan DPI)

For what it's worth, this works on much larger vehicles as well, but the sidewall stiffness becomes more of an issue because of the scale. https://www.komatsuamerica.com/equipment/trucks/electric/980e-5. Great work!